How does a horizontal or vertical labeller work?

Labelling machines are used in many sectors to package containers of products in the food, pharmaceutical, chemical, cosmetic, canning industries, liquid or solid.

Labelling machines are designed to label all shapes and sizes of products: cylindrical, conical, square, rectangular, flat, etc.

Also known as sticker applicators, industrial labellers are available in manual, semi-automatic or fully automatic versions. Depending on the model, type of container and sector of activity, these machines have different production capacities.

These machines are used to label various products such as: bottles, flasks, cans, cases, cartons, jars, tubes, blow-fill-seal, trays, pallets etc.

The labels or stickers can be used to identify or display the characteristics of a product (ingredients, …), to indicate legal requirements (expiry date, …) and possible promotions or any other additional information (logistics, conservation, …).

There are several types of labelling machines depending on:

– labels to apply: simple removable or non-removable labels, double labels, wrap-around labels, top and bottom labels (e.g. lid), …

– types of containers: cylindrical, rectangular, square, bulky, …

– container materials: plastic, iron, cardboard, …

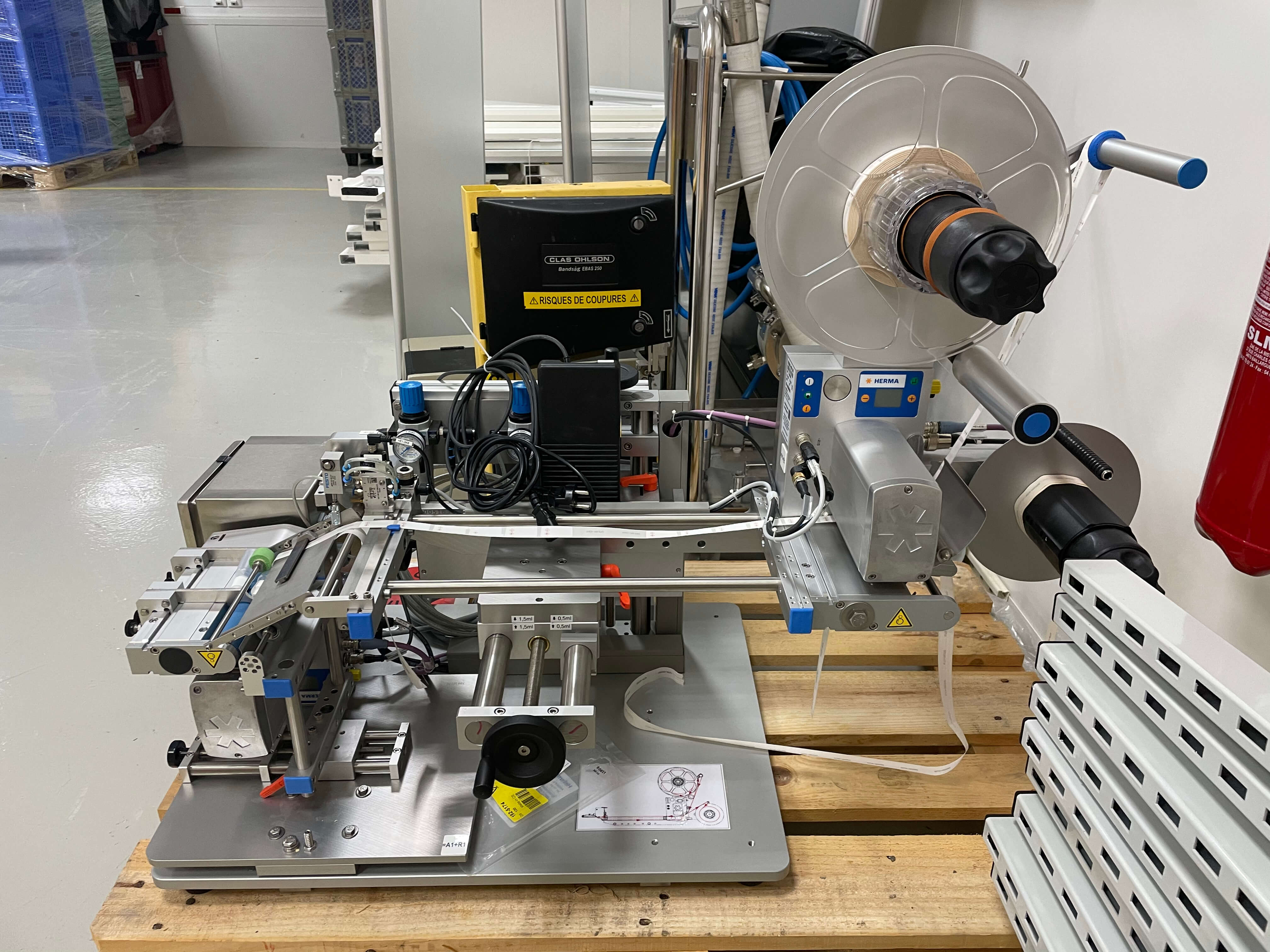

Automatic labeller

An automatic labelling machine performs and ensures the automatic labelling of products and primary or secondary packaging. This device, also known as a labeller, is used to apply self-adhesive labels onto a wide range of objects. Labelling machines are integral parts of packaging and wrapping lines. In some cases, they can be used to design the packaging.

Depending on how the container to label is placed, we refer to horizontal or vertical labelling machines.

Step 1: Feeding the elements to the label distribution area

The products to label are conveyed and moved to the labelling station by a conveyor system. At the same time, the labelling system starts moving at a continuous speed. Next, containers are conveyed to the label dispensing zone using a feeding system. Labels are positioned on the roll.

If the product is unstable or fragile, a crown accompanies it to the labelling station. Other labellers are equipped with a conveyor with adjustable guiding devices. This allows the machine to be adapted to different container sizes. Format changing can also be done by adjusting the size of the application rollers.

Step 2: Labels application on containers

Products are labelled on one or more sides depending on the settings selected. Containers are placed at regular intervals. The label is applied to the product during its passage in a continuous (lick labelling) or sequential (dab or lick labelling) way.

For cylindrical products, a dynamic lateral device allows the container to rotate during this process, allowing the label to be rolled up and applied naturally. Depending on the machine models, this rotation can be performed either stationary or in movement (automatic linear).

Step 3: Labelled container ejection

A sensor ensures that each label is placed correctly. The drive wheel can adjust the position to correct any errors on the label.

Labellers are equipped with a label detection system to check the presence of the labels. This feature detects and rejects products that are not labelled correctly.

Semi-automatic labeller

A semi-automatic labeller is a self-adhesive label applicator. These machines are mainly used with cylindrical or conical containers and packages.

These machines are easy and simple to use. The user manually deposits the object in the labelling position and activates a control lever.

The machine rotates the product and consequently applies the label until a complete and precise adhesion is achieved. The product is then manually discharged. These labelling machines can handle different formats and sizes thanks to the rulers on the machine.

Purchasing of a second-hand labeller

Buying a second-hand labeller remains a high investment for some companies. Prices vary depending on the condition, brand, location and year of manufacture of the machine. Osertech offers a wide range of equipment and machinery available, helping buyers to find the best used labelling machine opportunities.