Industrial and laboratory mills

The operation of a mill or granulator allows the volume reduction of products, raw materials or waste treatment. A mill is able to rapidly grind and shred large quantities of material.

Companies and laboratories generally use mills to achieve different tasks, such as improving storage conditions (space saving optimisation), transport, mixing and other process applications.

This equipment is used in the food and dairy, pharmaceutical, cosmetic, chemical, paper and biotechnology industries.

A distinction is made between different grinding solutions:

- Impact: movement of the product on the tool, movement of the tool on the product or impact between particles

- Crushing

- Attrition

- Percussion

- Abrasion

- Wear

- Shearing

These machines are generally classified according to the size of the particles they process

- Crushers

- Mills

- Pulverisers or micronisers

- Disintegrators

When purchasing a shredder, some points must be studied, such as the desired reduction rate (particle size), the nature of the raw material (hardness, friability of the products and their moisture content) and the size of the machine (quantity, volume, power consumption). The choice of the type of mill depends above all on the nature of the product to be ground.

Hammer mill

The hammer mill is used to reduce medium to heavy mass products by impacting the material with pendulum hammers. The product obtained by this mechanical action is transported through calibrated grids to the next stage of the transformation process. The final granulometry can range from medium to fine (granular or powder).

The hammer grinding mill consists of a grinding bowl with a thick and resistant shell. The ground product exits through openings in the grid. A rotor with hammers rotates inside the bowl. The speed of rotation can be variable. The hammer mill is mainly used for intensive industrial use.

The technology of the hammer mill differs depending on the use. The hammers will be more or less heavy and will rotate more or less quickly depending on the material and the required granulometry.

Cutting Mill / Blade Mill

Knife mills are commonly used in laboratories for the preliminary size reduction of soft, medium-hard, fibrous and hard materials.

The cutter mill allows the destruction/reduction of soft materials. A rotor inside the mill rotates at high speed. The product is cut between blades mounted on a fast rotating shaft and a fixed row of blades. The presence of a grid can ensure granulometric control at the outlet.

Ball mill

A ball mill consists of a horizontal drum set in rotation by a motor. It is partially filled with the product to be ground and the grinding elements (e.g. metal balls). Once the drum is rotating, a cascade phenomenon grinds the product to be milled into a fine powder. This equipment works according to the impact principle.

These industrial mills can operate continuously or in batch mode.

Pin mill

The pin mill is generally used to obtain a fine powder with a precise particle size. A pin mill is a machine that grinds materials by the action of pins that repeatedly move in front of each other. The materials are broken up by regular impacts.

The pin mill is a type of vertical shaft impact mill and consists of two rotating discs with pins embedded on one side. The discs are arranged parallel to each other, so that the pins of one disc face the pins of the other. The substance to be homogenised is introduced into the space between the discs. One or both discs rotate at high speed.

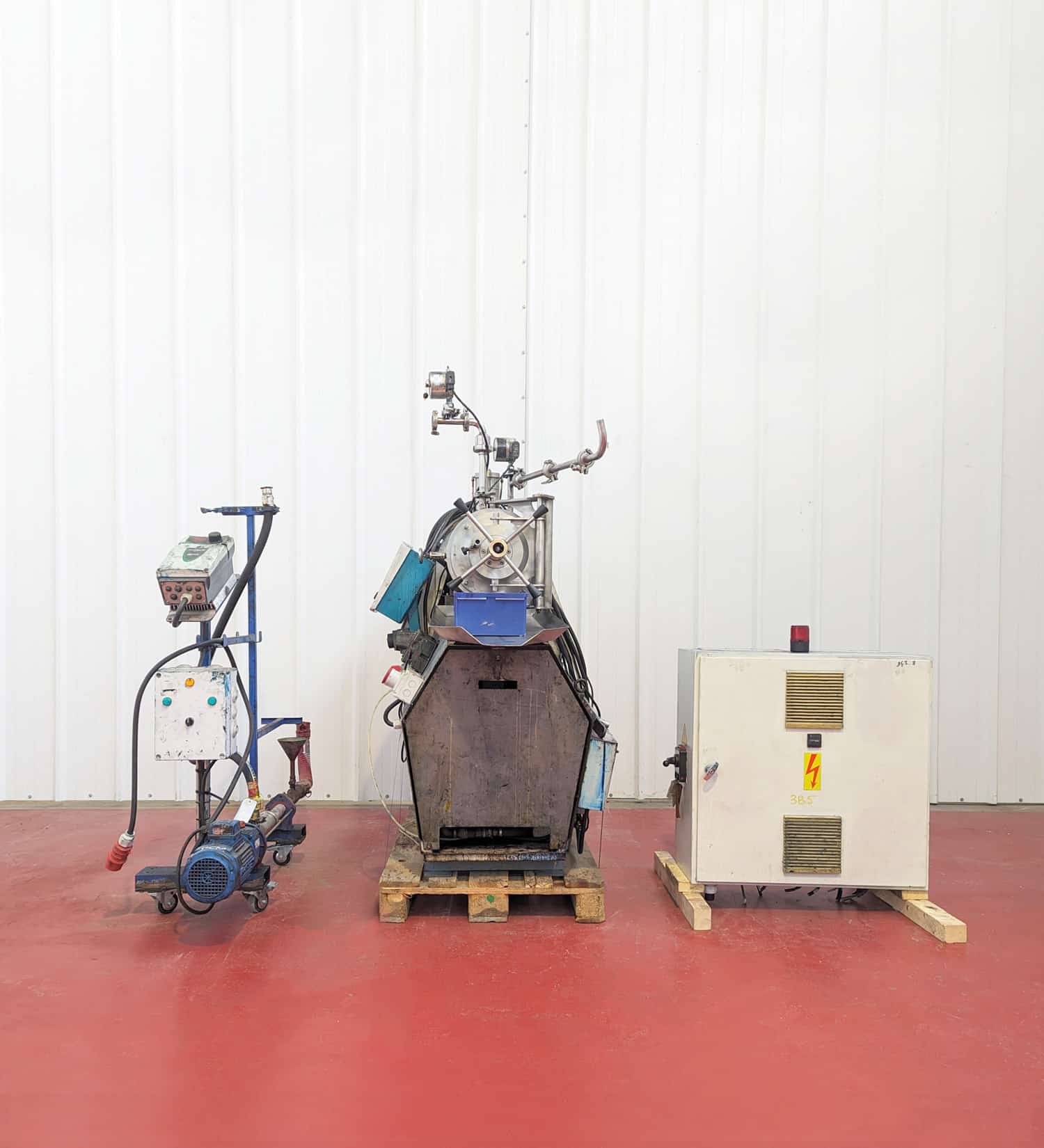

Colloid mill

A colloid mill is a machine used to reduce the particle size of a solid suspended in a liquid, or to reduce the particle size of droplets in emulsions.

Colloid mills operate on the rotor-stator principle: a rotor rotates at high speed. A high hydraulic shear stress is applied to the fluid, causing the structure to be disturbed and broken.

Microniser : What is micronization ?

Micronisation is a mechanical process using high shear to reduce the size of particles to a very small powder (100 to 500 µm). This increases the reactivity of a product, facilitates its handling and separates the components.

Micronisation can be carried out with a jet mill or a bead mill.

Piston homogeniser

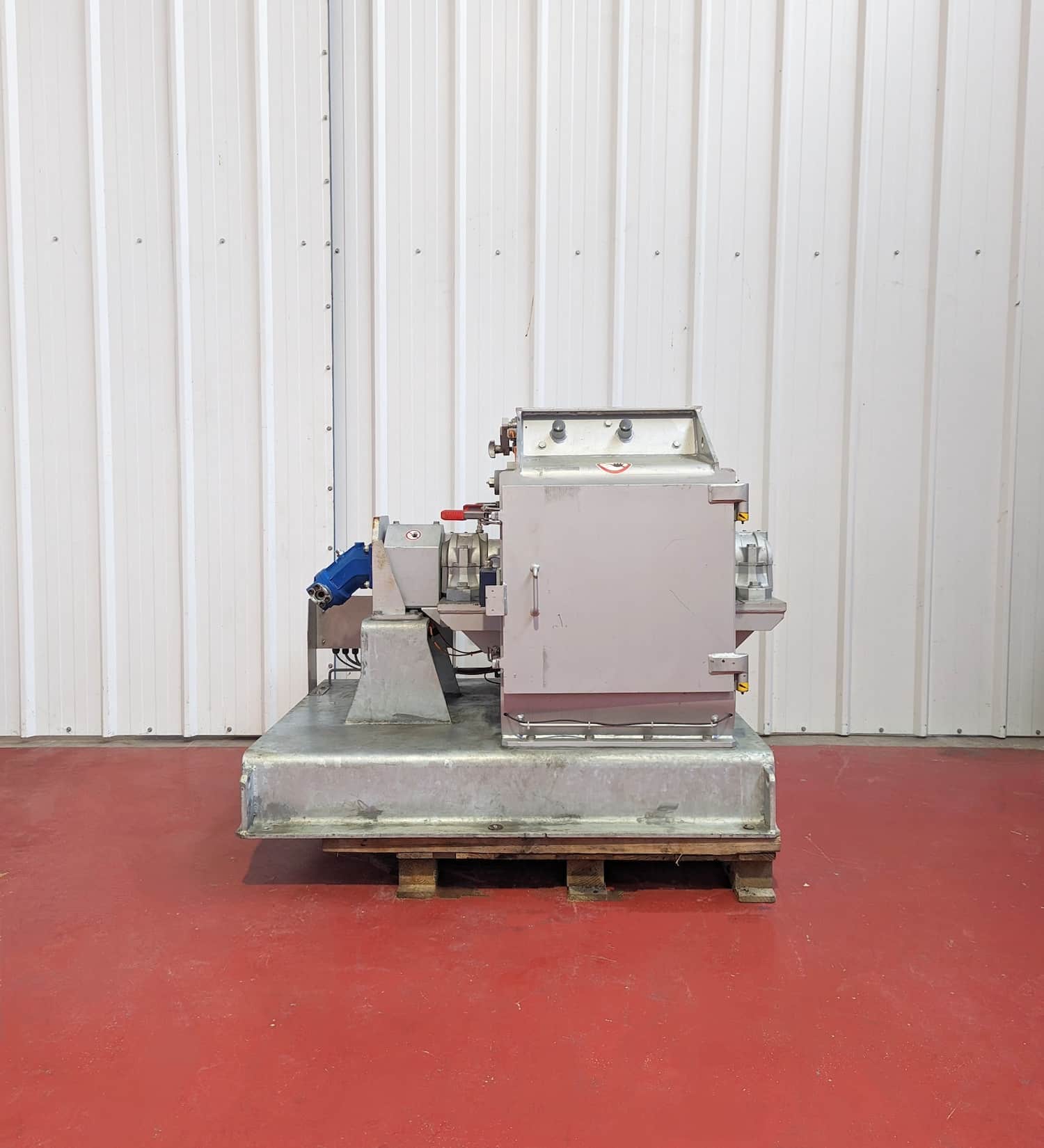

The high-pressure homogeniser or piston homogeniser is a device that consists of making two materials homogeneous, i.e. mixing them efficiently. It produces microscopic particles with the same grain size. It is then possible to mix two substances that do not usually mix.

The high-pressure homogeniser is used to create emulsions, nano-emulsions, micro-emulsions, dispersions, deagglomerations, encapsulations, cell breaks or particle size reduction.

Recognised brands: Retsch, FrymaKoruma, Fitz-Patrick, Frewitt, Hosokawa, Poittemill Forplex, …