VDI – Accumulation table

Manufacturer : VDI Type: Accumulation table Year : 2009 Automatic unit counting / detection system. Belt width : 20 cm Plate size : 80 x 120 cm

Home > Industrial machines available > Industrial transfer / conveying equipment > Conveying and feeding system

Manufacturer : VDI Type: Accumulation table Year : 2009 Automatic unit counting / detection system. Belt width : 20 cm Plate size : 80 x 120 cm

Type: vibrating conveyor Motor : Casadio Power: 0.06 Kw Outlet width: 160 mm Hopper volume: approx. 200 – 250 litres

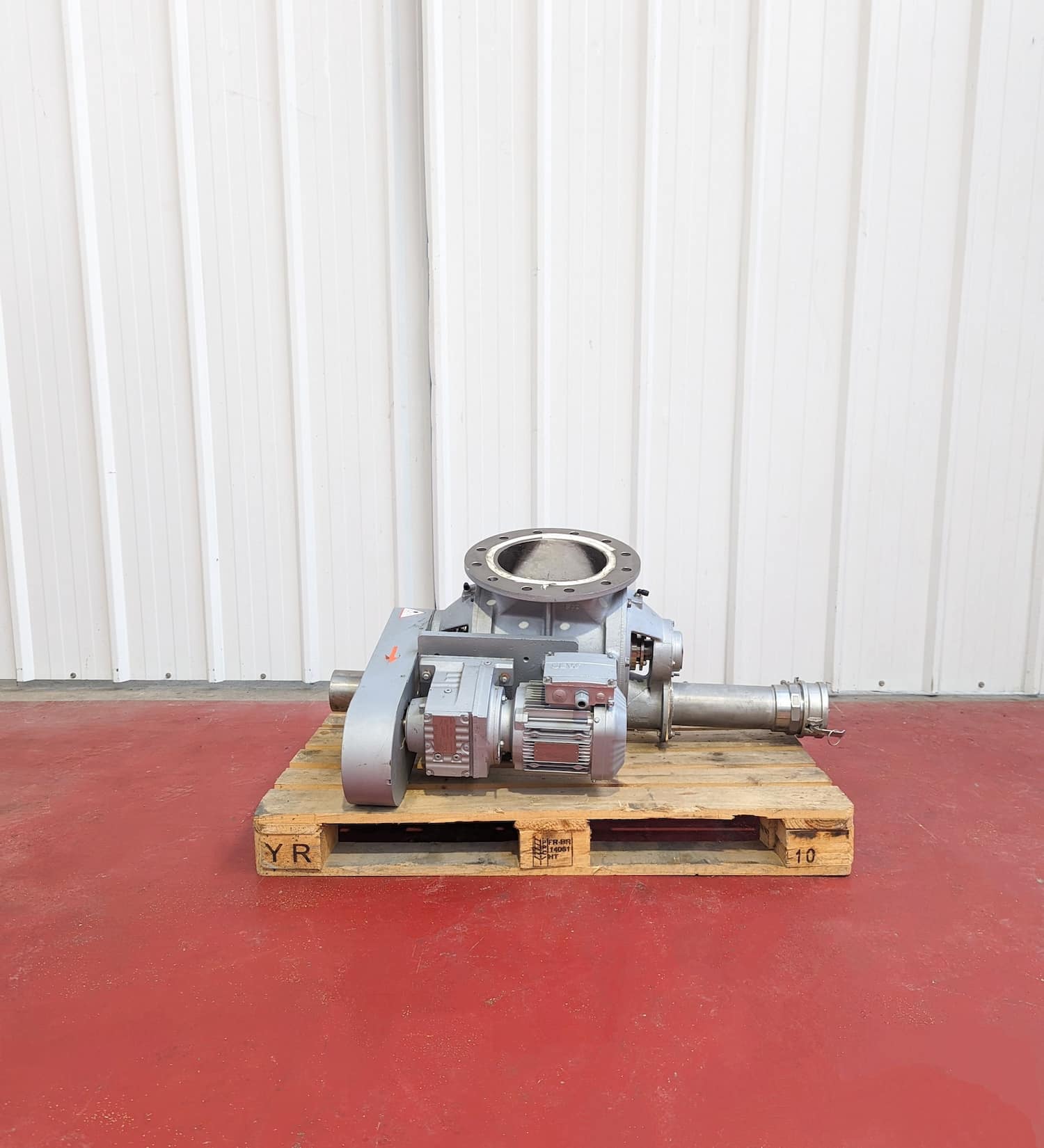

Type: Hopper and Rotary vane Materials: stainless steel (hopper) Nominal diameter: 600 mm. Motor power: 0.37Kw Pneumatic transfer Useful tank volume: 230 L

Manufacturer : DMN Model: BL 250 3N Year : 2012 Type : Rotary valve ATEX motor class : EX II 2G Ex e II C T3 External diameter: 405mm Nominal diameter: 250 mm. Motor power: 1.1 KW Sealing: air purge Rotor material: stainless steel

Fabricant : TBMA Europe BV Modèle : H-AR 150 Type : Vanne rotative Diamètre externe : 300mm Diamètre nominal : 150 mm. Puissance moteur : 0,25 KW Matériaux rotor : acier inoxydable

Manufacturer : DMN Model : BL 200/1 Type : Rotary valve External diameter : 345 mm Nominal diameter : 205 mm Leroy Somer motor : 0,75 KW Atex class : EX II 20 Tightness : Air purge

Manufacturer: TBMA Model: H-AR 300 Year : 2003 Type : Rotary valve External diameter : 450mm Nominal diameter : 300 mm. Motor power : 0,75 KW

Type : Rotating reception table Diameter : ø 145 cm Height : 104cm with adjustable feet Mechanical speed variator Transtecno electric motor 0.18 kW / 220-240 V

Type : Reception turntable Diameter : ø 100 cm Mechanical speed variator Materials : stainless steel

Manufacturer: Ozaf srl Model: E 10 Year : 1995 Type : Elevating belt with cleats / Giraffe conveyor. Power : 1,5 Kw Equipment: vibration system Overall dimensions: 65 x 135 x 190 cm Dumping height: 120 cm

Documentation Multievacuator 140.pdf Additional information Pneumatic conveyor belt. Suction operation for powders or granules. The Multi-evacuator unit is a combination of blower and cyclone, designed for the suction of granular materials. The upper part, containing the impeller, can be opened for easy cleaning and replacement of the cyclone filter basket. The fan creates the necessary vacuum to draw the material

Osertech is specialised in the trading of used industrial equipment. Since 1994, the company offers services in buying and selling equipment and machinery in France and worldwide.