Difference between a bead mill and a ball mill:

Ball and bead mills are two different types of equipment. However, there is a certain similarity between these two types of equipment. The bead mill has been developed on the basis of the ball mill. Both types of machines use collision, extrusion or friction as grinding power.

Ball Mill

A ball mill consists of a horizontal drum that is rotated by a motor. It is partially filled with the product to be ground and grinding elements (e.g. metal balls). The cylinder rotates at low speed and has no internal mixer.

Once the drum is rotating, a fall process grinds the product into a fine powder. This equipment works on the principle of impact. The movement of the balls and their potential gravity energies are used to cut, crush and rub the product against the cylinder wall. The ball mill generally uses steel balls that are loaded into the chamber in different diameters and proportions depending on the product.

The ball mill is the key equipment for crushing materials after they have been crushed (e.g. fertilizer, building materials, waste recycling, etc.)

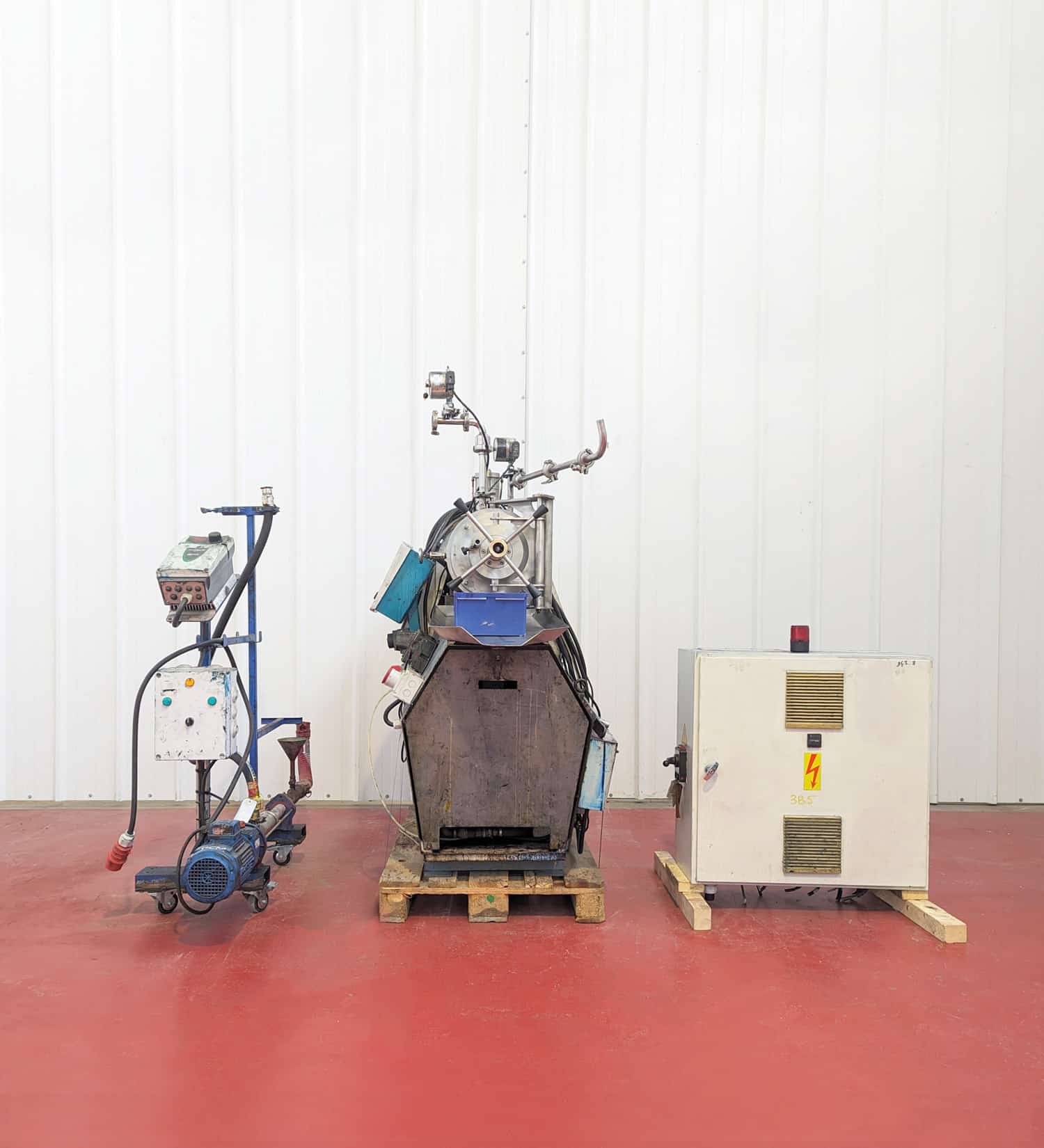

Bead / sand mill

Bead mills and sand mills are same machines. The milling chamber is fixed. A mixing shaft in the cylinder transmits kinetic energy to beads present into the cylinder. They crush the product into fine particles. Bead mills are dispersion processing machines, where solid particles (pigments, fillers, …) are reduced in size and finely dispersed and impregnated in a liquid phase for exemple.

There are vertical and horizontal sand mills, with disc, pin or rotors. The grinding fineness can be up to 100 nm or 50 nm.

Bead mills are mainly used for wet grinding of chemicals / pharmaceuticals liquid and solution. These industrial mills can operate in continuous or batch mode.