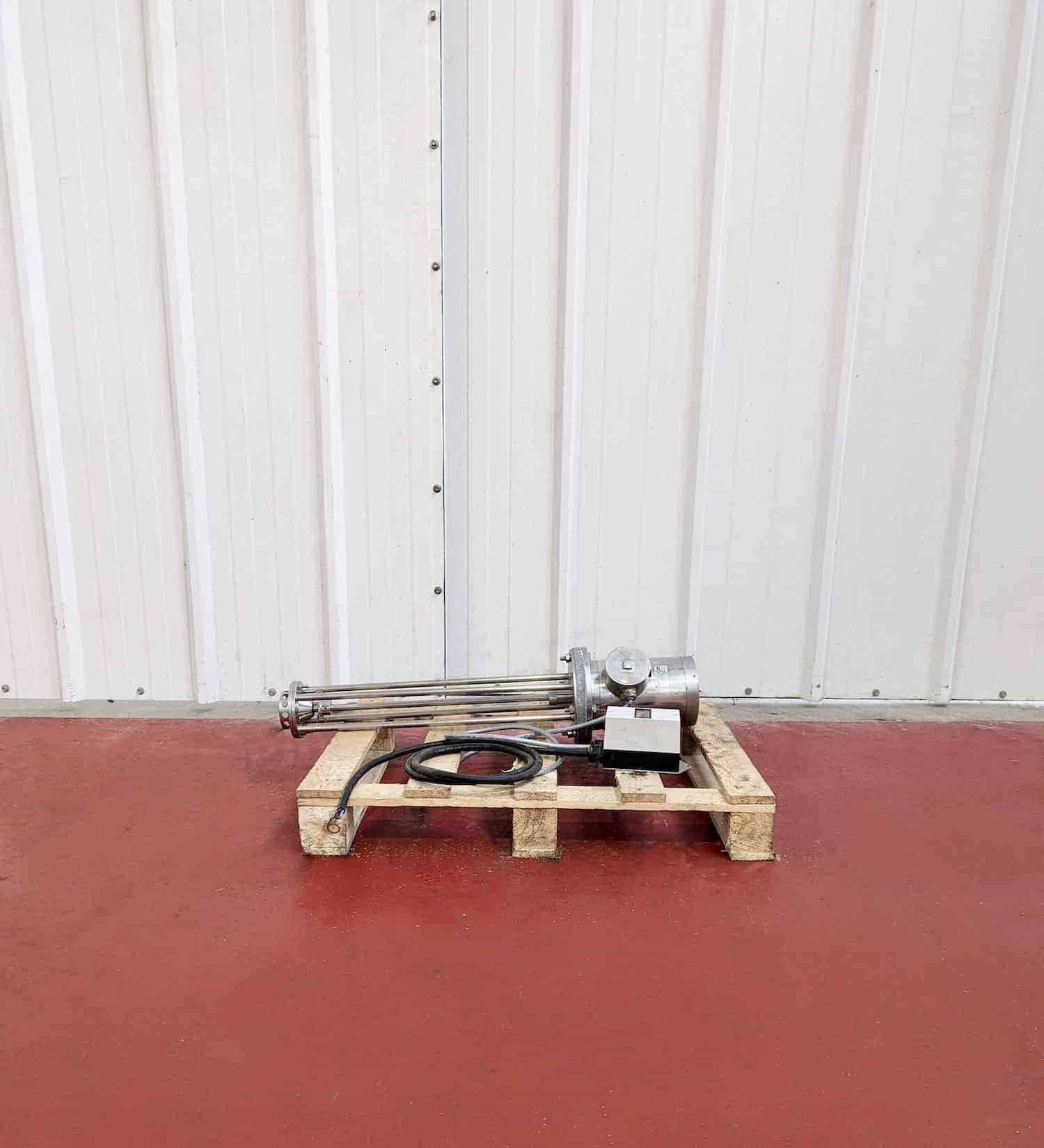

Moritz – Mixer

Manufacturer : Moritz Type : Stirrer / mixer Motor: CEM Power : 2,2 kW Speed: 1420 rpm Stator head diameter: Ø 250 mm Total agitator shaft length: 750 mm

Home > Industrial machines available > Industrial mixer > Stirrer

Manufacturer : Moritz Type : Stirrer / mixer Motor: CEM Power : 2,2 kW Speed: 1420 rpm Stator head diameter: Ø 250 mm Total agitator shaft length: 750 mm

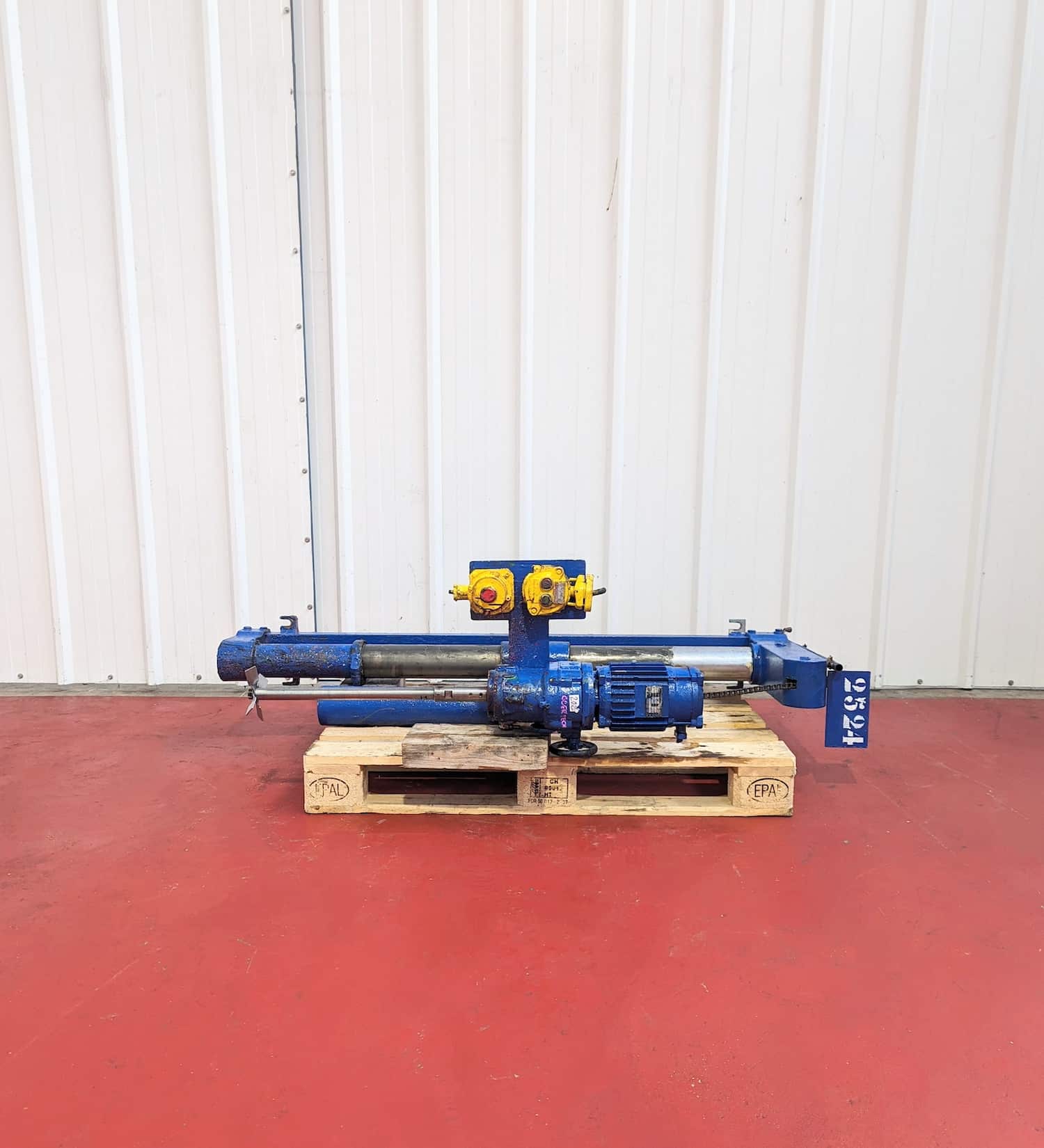

Manufacturer : Silverson Motor: Marlin Power: 0.75 KW Type: Vertical High Shear Mixer | Immersion Mixers Stirring mechanism: Versatile disintegrating head, recommended for disintegrating solids and preparing gels, thickeners, suspensions, solutions and slurries. Speed: 2900 rpm Head diameter: Ø 120 mm Total length: 900 mm

Type : Stirrer Wall support: manual Previous use: paint Motor power : 0,5 KW Classification: Explosion-proof GR.III Stirring mechanism: dispersing tool Mixing head diameter: 150 mm Mixing shaft length: 575 mm Up/down movement: 900 mm

Type : Stirrer Wall support: manual Previous use: paint Motor power : 0,5 KW Classification: Explosion-proof GR.III Stirring unit: Turbine with inclined blades Mixing head diameter: 150 mm Mixing shaft length: 575 mm Up/down movement: 900 mm

Remaining units available: 10 Manufacturer: VMI Rayneri Model: Turbotest 33/300 Year: 1997 to 2000 Type: Laboratory stirrer Version 1: Turbotest Type 33/300 P Electrical supply: 220 V Power: 440 W Intensity: 2A Max speed : 3300 rpm Variable speed of mixing. Container fixing system. Product presence contact detection. Each equipment is sold with an stirring shaft and a mixing

Explosion proof motor 3 KW (ADF / ATEX: EExdellCT4) 2870 rpm IP 55 Turbine D.125 Volume, max. with H2O): 5000 l Viscosity, max. 15000 mPas Process pressure (max.) 0 bar Vacuum, max. 100 mbar Process temperature, max. 120 °C Mixing tools Propeller Motor power, standard 3 kW Shaft size D.40 X L.1000 Weight approx. 42 kg New sealing cartridge installed

4-wheel mobile chassis with locks. Up/down: adjustable stirring height. Removable plate. Motor: ATB – Antriebstechnik G. Bauknecht GmbH Power: 0,55 KW Atex class: EExe II T1/T2/T3 Siemens variable speed drive Dimensions: 70 x 105 x 200 cm.

Details Dispersion tool : rotor-stator Brand : IKA – Werke Gmbh & co Model : UTC T 150 Year : 1999 Motor power, standard : 11 kW Motor power, max. 13 kW Viscosity, max. 5000 mPas Modification made by our team: Installation of a new sealing shaft (from manufacturer), see photo.

Hydraulic crane capacity 1000 kg Single-action pump Safety valve in case of overload “Dead man’s” controls Chrome-plated chopstick Speed : 1370 rpm /min

– Mobile stirrer unit on 4 wheels – Pressure control actuator: Safety shutdown / motor stop in high position – 4 agitation heads – ATEX equipment: Eexe II T3 – Variable mixing speed: 465 – 2800 1/min – Power 0.55 kW – 230/400 V

Industrial stirrers and overhead stirrers for laboratory are used in industries manufacturing a product by synthesis or mixing. This equipment can be found in the chemical, food, pharmaceutical, cosmetics industries, etc…

Agitation is achieved by bringing the final phase into motion. The mass can be composed of different substances. The purpose of the operation is then to homogenise it or to connect reagents in order to make them react more efficiently. Otherwise, the mass may already be homogeneous and the stirring operation enables a heat transfer or a maintenance of solid particles in suspension.

The choice of agitator depends on the phases to be stirred (single phase or multi-phase): liquid, solid or gaseous. Depending on the type of phase and the viscosity of the mixture, the agitator can be called by different names: mixer, stirrer, kneader, etc.

There are different types of mixers and stirrers available on the market: mechanical, static, rotating tank, by propulsion of a jet of liquid thanks to a pump, generated by a gas.

Liquid agitators can be located vertically from the top, horizontally and more rarely on the bottom of the tank.

An agitator is composed of a motorisation, a shaft guide mechanism, a shaft and an agitator device. Made of stainless steel (inox), agitators are essential for the production of finished products in many industrial sectors.

In the chemical industry, tanks / vessels / blenders with agitators are used in the production of liquid, pasty or viscous products.

In the paper sector, where the quality of the paste and its homogenisation directly determine the quality of the finished product, the conception of suitable tanks is a real necessity.

In the food industry, for example, tanks are essential for the manufacture of dairy products, alcohols, fruit juices, etc. The mixing stage is performed by avoiding any alteration in the texture or quality of the ingredients.

In the animal feed industry, the objective is to ensure that the balance of the product mix is well respected.

Note: these impellers, more commonly known as propellers, create an axial flow in the tank. Propellers are generally used to homogenise mixtures with low to medium viscosity. They are used for suspending solids, for crystallisation or for creating liquid-liquid dispersion.

Note: These impellers are more simply called turbines. They are used in processes such as fermentation, gas-liquid chemical reactions or in the manufacture of emulsions (liquid/liquid).

Osertech is specialised in the trading of used industrial equipment. Since 1994, the company offers services in buying and selling equipment and machinery in France and worldwide.