How mixers work ?

Mixers are used in all sectors of industry to blend, mix, homogenise, emulsify, dissolve or obtain reactions with one or more components. This equipment can process products in liquid, solid or semi-liquid (viscous) form, such as creams, powders or oils.

A mixer generally consists of a motor and a stainless steel tank (open or closed) into which the substances to be mixed are injected. The mixer may also be fitted with a hopper or a feed system. Depending on the product, there are different types of mixer.

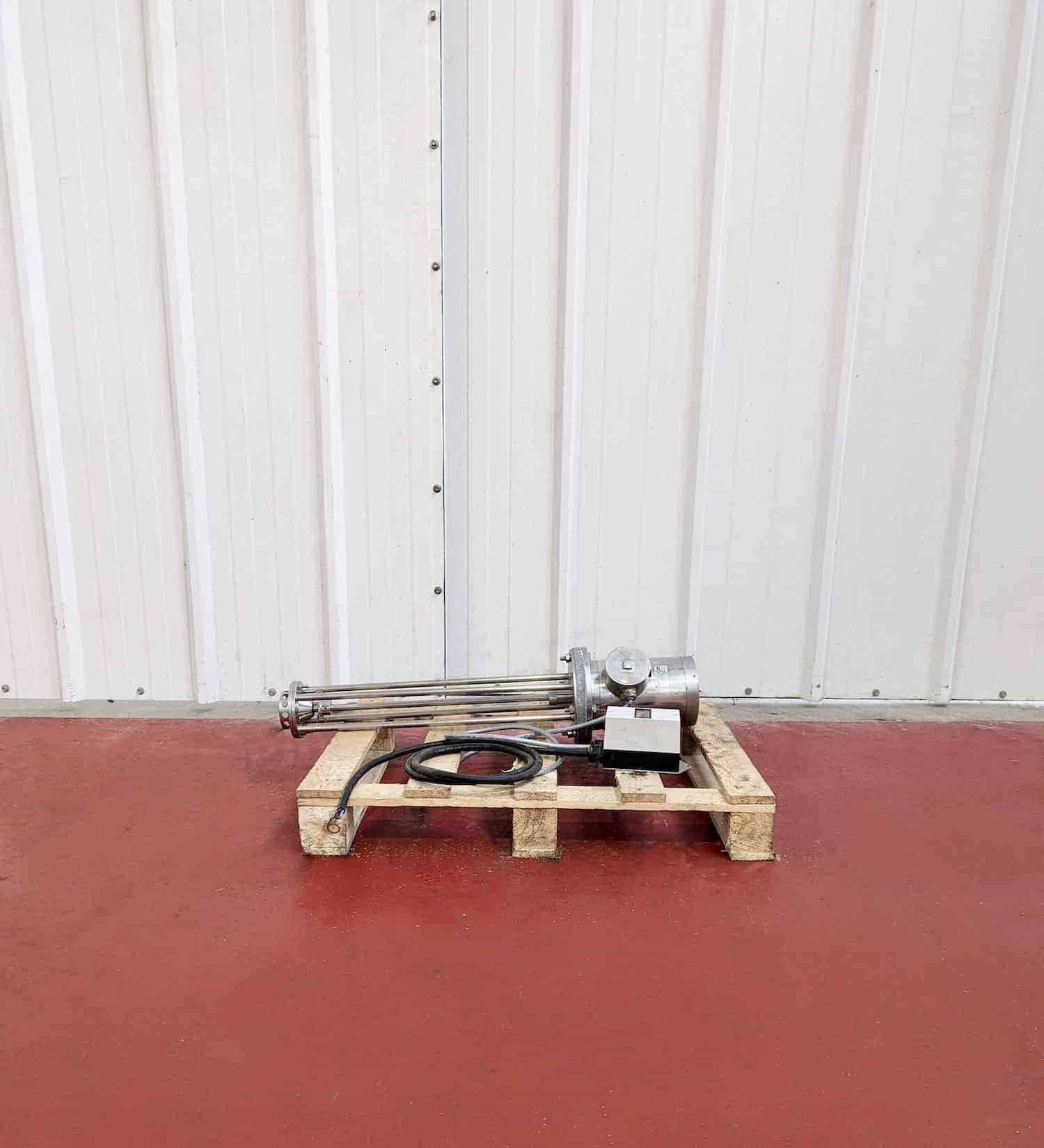

A mixer consists of a motor that drives a rotating shaft with one or more mixing tools (blades, ploughshares, propellers, scrapers, rotors, etc.) attached to it. If necessary, a mechanical seal ensures the dynamic sealing of the rotating shaft with the vessel through which it passes.

Mixers are widely used in :

- the food industry for the manufacture of food products (for human or animal consumption);

- the pharmaceutical sector for the manufacture of premixes and solutions;

- the cosmetics sector, for the creation of creams, lotions, shampoos, etc;

the chemical industry for the safe production of delicate mixtures and reactions.

Cream mixers and viscous products

Used in the pharmaceutical, chemical and cosmetics industries, vacuum mixers allow a product to be mixed in a controlled atmosphere (vacuum). The vacuum vessel provides a working environment where no oxidation occurs, guaranteeing the quality of the mixed product and the emulsifying effect. The vacuum also eliminates any bubbles generated during the mixing, dispersing or homogenising process. It can also be used to transport ingredients from aqueous phases (oil, water, etc.) to the main mixing chamber.

For processing viscous products such as cream, these mixers are equipped with anchor blades, counter-stirring, emulsifiers (rotor/stator), scrapers, etc.

Powder and granule mixers

When it comes to mixing powders, ploughshare, ribbon or rotary mixers are generally used, depending on the process required.

Ploughshare mixer

The ploughshare mixer is designed for heavy-duty mixing of dry and wet products. It creates a mechanical mixing action in a fluidised bed. This mixer has a very good mixing effect for materials with a wide range of sizes and densities.

It consists of a cylindrical drum containing ploughshare-shaped mixing elements mounted on a horizontal shaft. The mixing ploughshares project the material away from the wall into the free space, in a crosswise direction, and vice versa.

The ploughshares separate and lift the product in a three-dimensional movement, while the number and arrangement of the ploughshares ensures forward and backward mixing along the entire length of the tank.

If necessary, the mixing action is assisted by high-speed choppers known as cutters. These rotating knives are mounted on independent high-speed motors with specific blades to add shear to product mixes.

Ribbon mixers

Ribbon mixers operate on two mixing principles: convection and diffusion. Convective mixing involves macro-movement of large parts of the solids. Convective mixing occurs when the solids are turned over along the horizontal mixing axis.

The other type of ribbon mixing is diffusion mixing, which is the micro-mixing that occurs when individual particles are moved relative to the surrounding particles. In the ribbon mixer, diffusion occurs when particles at the front of the ribbon are moved in one direction while neighbouring particles are not moved or lag behind. Together, these two types of action result in the mixing and homogenisation of solids.

The ribbon mixer consists of a horizontal U-shaped vessel and a ribbon spiral agitator specially designed to rotate inside. The ribbon mixer is based on a proven agitator construction that provides a triple slow mixing action ensuring fast and efficient mixing. The ribbon dimensions and configuration are carefully balanced to ensure continuous movement of the material through the container, avoiding dead spots and allowing rapid product discharge.

The ribbon mixer is a lightweight mixer, generally used for easy to mix powder components that are pre-processed, such as dry granules, pre-dried powders, etc. It is a low shear mixer and is mainly used for SOLID / SOLID mixing. It is a low shear mixer and is mainly used for SOLID / SOLID mixing.

Rotary Drum Mixer and V-Blender

The V-blender enables solids/solids in any proportion and solids/liquids in powder or granular form and with different specific weights to be mixed gently.

The V-shaped solids mixer, with rotating drum, is used for mixing fragile products or for applications with high cleaning requirements between cycles.

It features a rotating drum that rotates at low speed. By slowly sliding the solution along its smooth inner walls, it mixes the product without forcing it.

Thanks to the characteristic V-shape, axial flows are created inside the tank that separate and unite the product to be mixed. The result is a fast, uniform process without the use of blades or other mechanical devices.

Rotary mixers can also be cylindrical, like a turbine, or cubic, like a container mixer.

Liquid and solid mixers

A wide range of agitators are available for mixing liquid and solid products (click on the link to find out more). The process can also take place with certain inline mixers. Fitted with a feeding hopper, the in line mixer releases the solid product into the liquid to homogenise it. The solution is then discharged into a vessel.